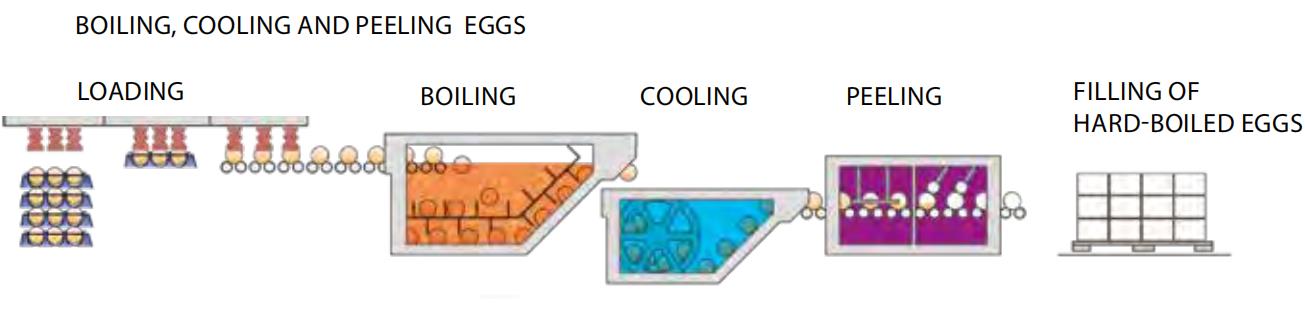

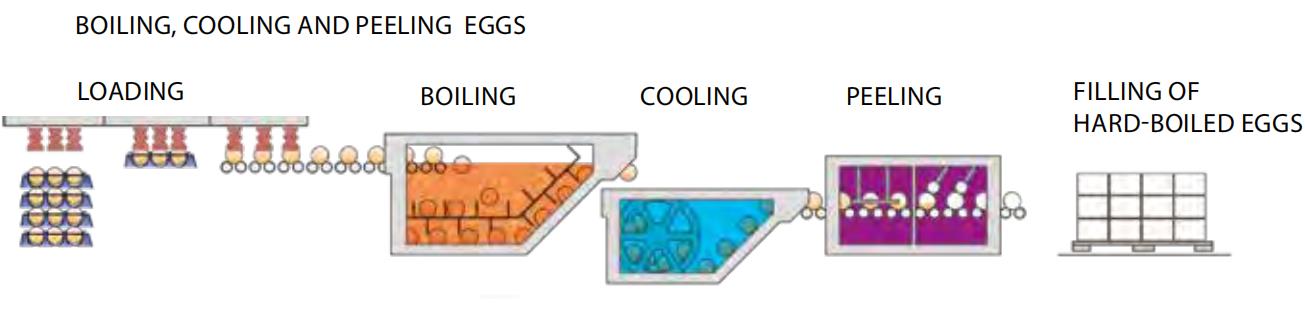

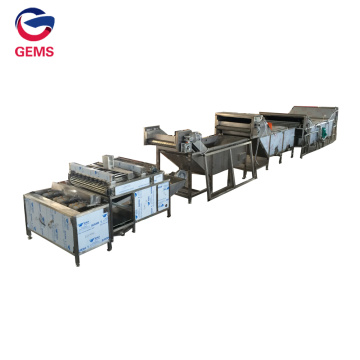

Product Description

Introduction of Hard-Boiled and Peel Eggs Processing Machines

The advantages of our egg boiling and shelling production line:

1. Centering steaming, not yellowish

The processing process of shelled eggs is mainly to ensure the yield after shelling, and the key issue to ensure the yield is: the yellowish problem of quail eggs during the cooking process. The quail egg cooking process developed by our company is divided into two parts: centering cooking and steaming. For the centering area, a special structure principle is adopted to ensure the centering and cooking of quail eggs without yellowing, thereby ensuring the yield.

2. Save labor and high production efficiency

The assembly line has automatic continuous cooking, chain drive, and is equipped with a speed adjustment function (boiling speed and water flow speed are adjustable), simple and safe to operate, reduce labor intensity, improve cooking efficiency, save labor, and reduce labor costs.

3. Energy saving and environmental protection

The pipeline heating method adopts boiler heating or electric heating. The patented steam leakage prevention structure can effectively prevent the steam from overflowing and help maintain the temperature in the steamer. The double-layer insulation structure greatly reduces energy consumption and has excellent energy saving and environmental protection characteristics.

4. Convenient operation, high strength, low operating temperature and low failure rate

The assembly line and the whole machine are made of high-quality stainless steel, with double-layer mesh belts and water as the medium. The modified machine runs smoothly, with stepless frequency conversion speed regulation, low noise, high strength of the stainless steel mesh belt, low flexibility, not easy to deform, and easy to maintain.

Final Effect of Hard-Boiled and Peel Eggs Processing Machines

For This automatic line, the function of centering yolk is very important. If the centering yolk is not good, the eggs will be broken during peeling.

The capacity of Hard-Boiled and Peel Eggs Processing Machines

We have 3000eggs/5000eggs/8000eggs/10000eggs/20000eggs per hour, you can choose the suitable one according to the demands.

Beside this fruit vegetable washing machine, we also provide fruit vegetable blanching machine, fruit vegetable dehydrator machine, fruit vegetable crusher, hydraulic press machine to get fruit or vegetable juice. Please contact me for details:

Contact Now

Contact Now