Product Description

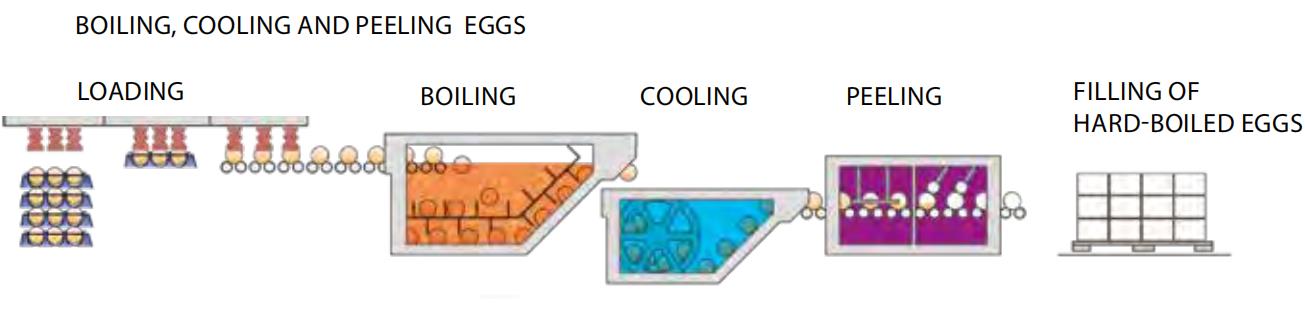

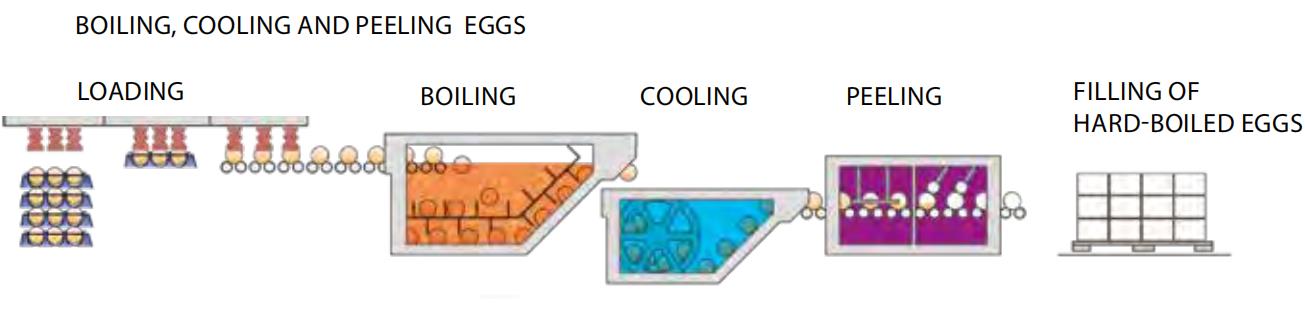

Introduction of Brown Eggs Boiling Cooling and Peeling Machines Line

1. When boiling and peeling eggs, the focus will be on the appearance of the eggs for the consumer and the shelf life of the boiled eggs.

2. The eggs must be peeled with a minimum scratching in the egg white surface, no egg shell fragments in the egg white, and the yolk placed in the center of the egg. All of this is taken care of in the GEMS Hard-Boiled Egg Systems.

3. Our long experience within egg industry has been used for designing the line, and a big step has been taken to improve the yield rate for both white and brown eggs.

4. The eggs are finally peeled in the peeling machine before they continue towards the inspection conveyor prior to packaging.

We can customize this egg boiling and shelling line based on your demands.

Features of Brown Eggs Boiling Cooling and Peeling Machines Line

1. The Hard-Boiled Egg System automatically boils, cools, and peels up to 3.000-20,000 eggs/hour.

2. Up to 98.5% yield rate on both white and brown eggs on the boliling unit is achieved.

3. Up to 98% yield rate on the peeling unit is standard.

4. It peels both brown and white eggs.

5. The peeling technique has reduced the shell impact to nearly zero.

6. Optimized control and encapsulation decrease energy consumption.

7. There is a yolk centering system.

8. Easy access to equipment reduces the cleaning time.

Final Effect of Brown Eggs Boiling Cooling and Peeling Machines Line

For Brown Eggs Boiling Cooling and Peeling Machines Line, the function of centering yolk is very important. If the centering yolk is not good, the eggs will be broken during peeling.

The capacity of Brown Eggs Boiling Cooling and Peeling Machines Line

We have 3000eggs/5000eggs/8000eggs/10000eggs/20000eggs per hour, you can choose the suitable one according to the demands.

What is more, we also have the fruit vegetable washing machine, fruit vegetable crusher, fruit vegetable juice extrator and hydraulic press machine to make fruits juice. Please contact me for details:

Contact Now

Contact Now